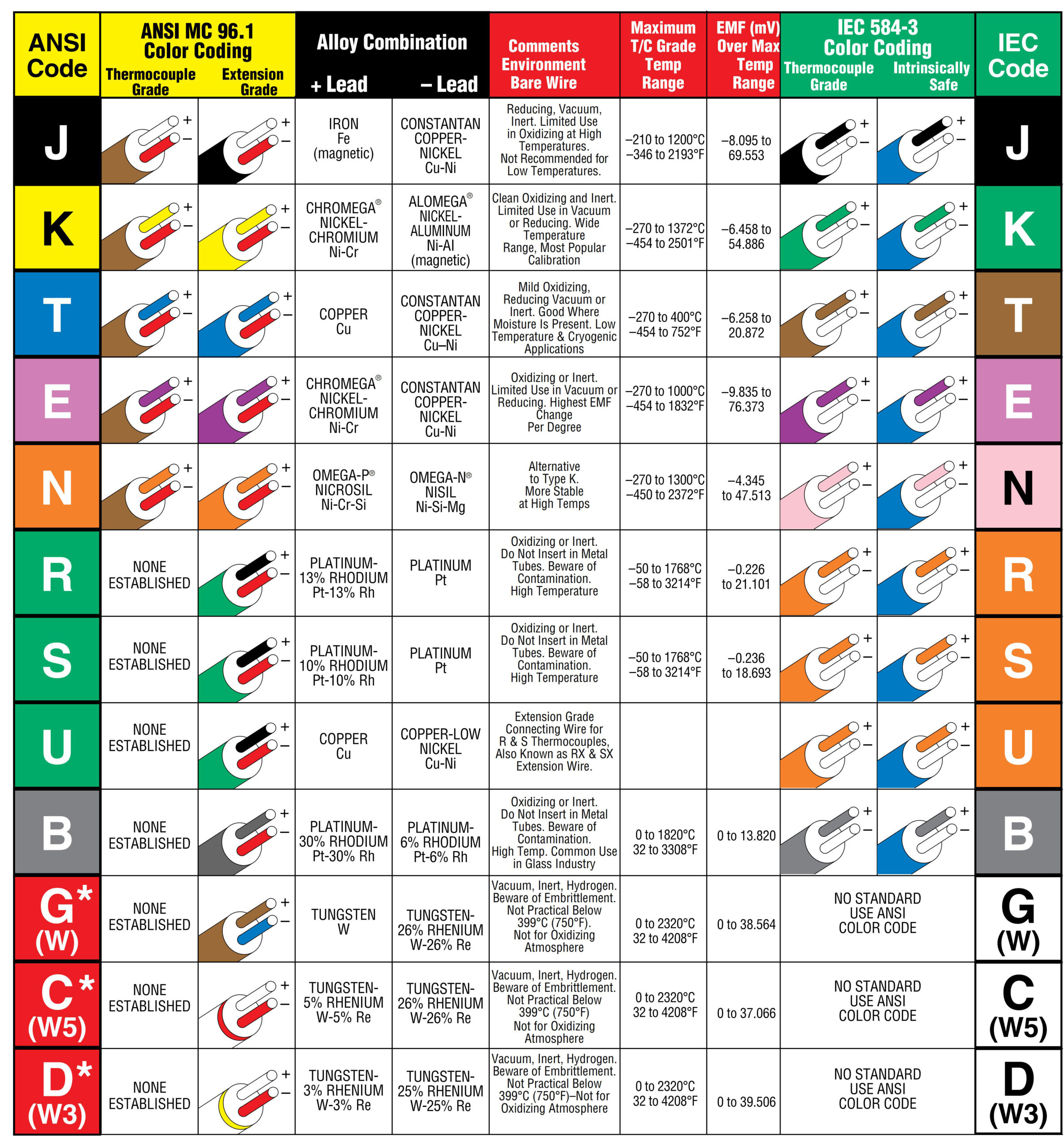

Kode Warna ANSI dan IEC untuk Kabel Termokopel

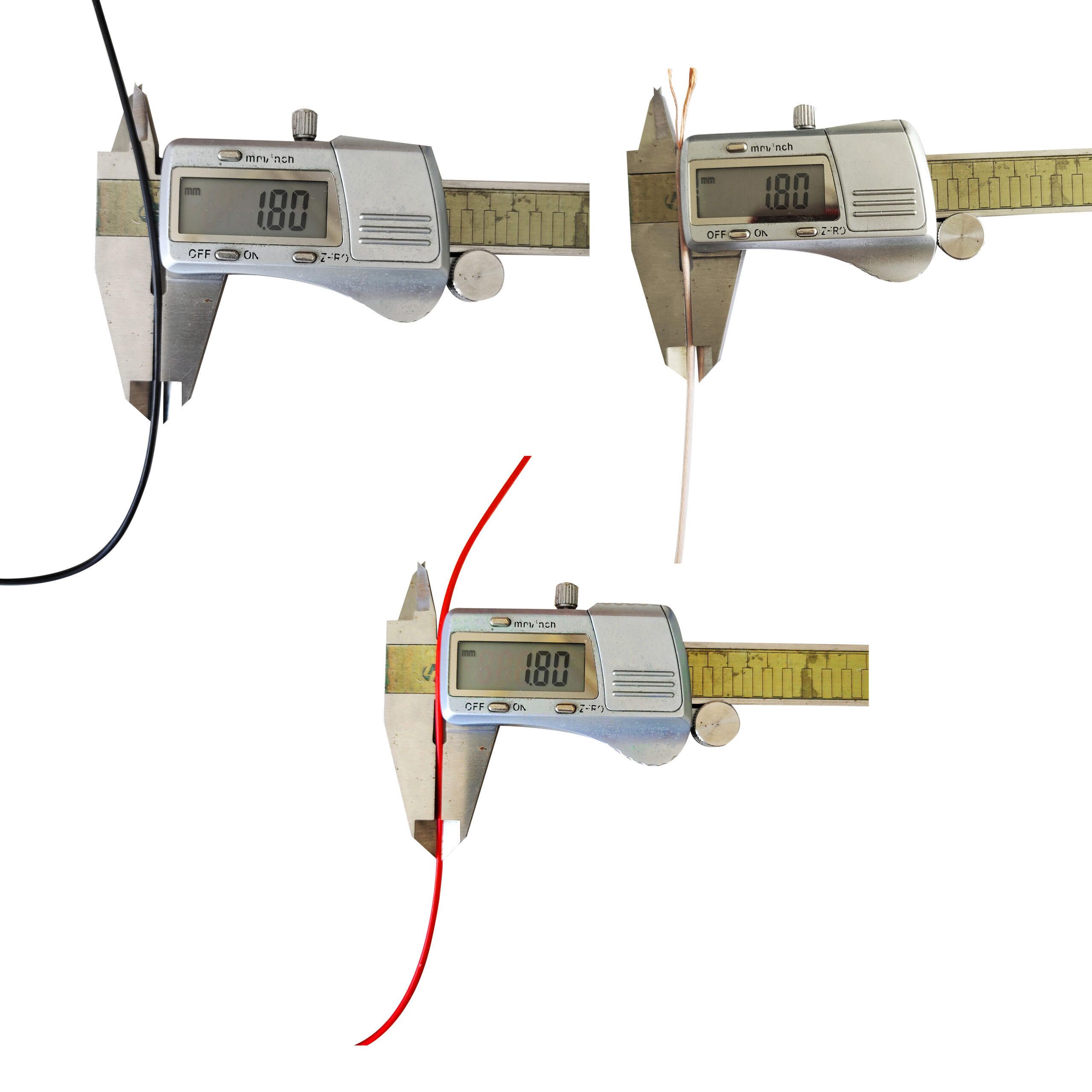

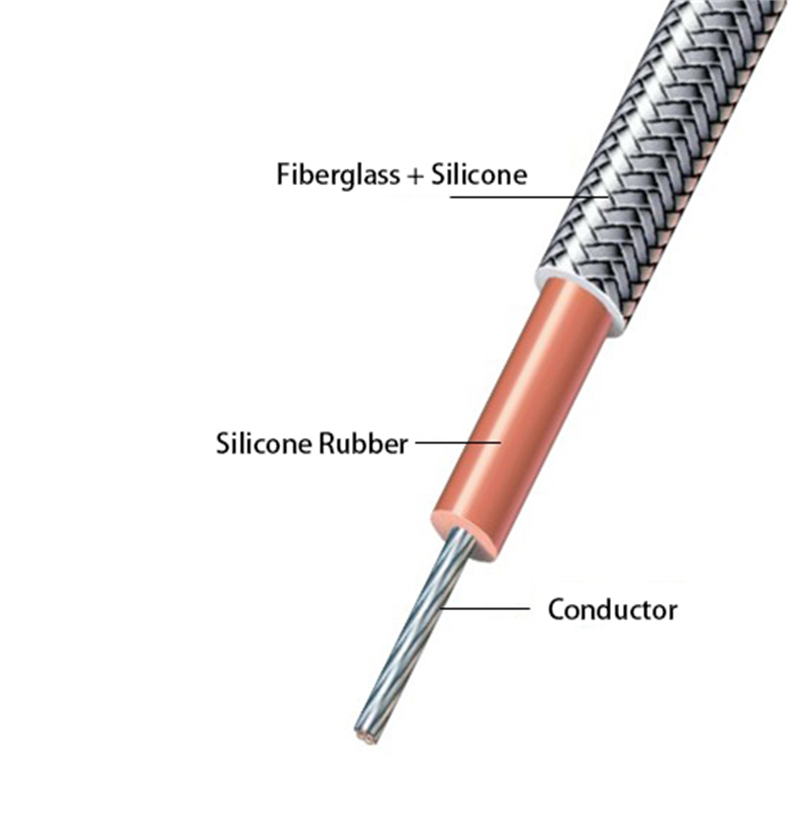

It’s customized super soft silicone wire for baby car toy

| Nomor Bagian Shoayer | SYAGCR-0-20/273 | |

| Tegangan Terukur | 300/500V | |

| Nilai Suhu | -60℃ ~ +200℃ | |

| Konduktor | Bahan | tembaga telanjang |

| AWG | 2AWG | |

| SYRVVP-0-4 | 7/39/0.05mm | |

| Diameter | 1.0mm | |

| Isolasi | Bahan | Karet silikon |

| Ketebalan | 0.40mm | |

| Diameter luar (mm) |

1.80± 0,05 mm | |

| Warna | Pilihan | |

| Paket | 2000m/spool | |

| Perkirakan berat | 7.1km/kg | |

| Resistansi konduktor maksimum DC 20℃ | 34Ω/km | |

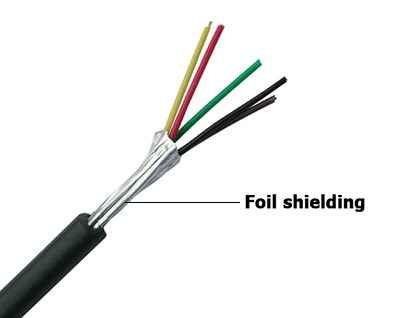

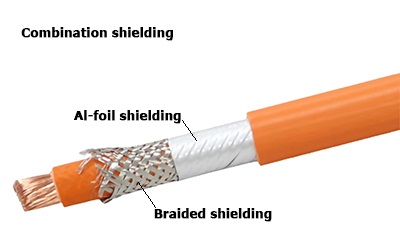

There are three common types of shielding used in cables: foil shielding, pelindung dikepang, and combination (foil and braided) shielding.

1. Foil shielding: Foil shielding consists of a thin layer of aluminum or copper foil wrapped around the cable. It provides protection against electromagnetic interference (EMI) by preventing external electromagnetic signals from entering or interfering with the signal transmitted through the cable. Pelindung foil sangat efektif pada frekuensi tinggi.

2. Braided shielding: Braided shielding is made up of a woven mesh of fine metal wires, biasanya tembaga atau tembaga kaleng. Ini menawarkan fleksibilitas luar biasa dan memberikan tingkat perlindungan EMI yang lebih tinggi dibandingkan dengan pelindung foil. Pelindung yang dikepang sangat efektif pada frekuensi rendah dan memberikan cakupan yang lebih baik terhadap medan magnet intensitas rendah.

3. Combination (foil and braided) shielding: Combination shielding combines the advantages of both foil and braided shielding. It provides a high level of protection against both EMI and radio frequency interference (RFI) across a wide frequency range.

Keseluruhan, bahan pelindung ini membantu menjaga integritas dan kualitas sinyal listrik yang dikirimkan melalui kabel dengan meminimalkan interferensi dari sumber elektromagnetik eksternal. Mereka memastikan bahwa sinyal yang diinginkan tetap kuat dan jelas, sehingga meningkatkan kinerja keseluruhan dan keandalan sistem kabel.

Tingginya jumlah pesanan minimum untuk kabel dan kabel material PTFE dapat disebabkan oleh beberapa alasan.

1. Specialized Material: PTFE is a specialized and high-performance material with exceptional electrical insulation, tahan panas, ketahanan terhadap bahan kimia, dan sifat tahan kelembaban. Hal ini membuat kabel PTFE cocok untuk aplikasi yang menuntut di industri seperti dirgantara, telekomunikasi, dan peralatan medis.

2. Complex Manufacturing Process: PTFE cables require a complex manufacturing process and specialized equipment. Biaya produksi umumnya lebih tinggi dibandingkan dengan bahan standar. Untuk memastikan pemanfaatan fasilitas dan sumber daya produksi secara efisien, produsen sering kali mengharuskan pelanggan untuk memenuhi jumlah pesanan minimum yang lebih tinggi.

3. Limited Availability of Raw Materials: PTFE raw materials are sourced from a small number of suppliers. Ketersediaan yang terbatas ini dapat menaikkan biaya dan memerlukan pesanan yang lebih besar untuk membenarkan biaya produksi dan pengadaan.

4. Customization Requirements: PTFE wires and cables often require customization based on specific requirements such as insulation thickness, ukuran konduktor, dan bahan jaket. Menyesuaikan jumlah yang lebih kecil dapat memakan waktu, tidak efisien, dan mahal bagi produsen. Karena itu, mereka lebih memilih jumlah pesanan minimum yang lebih tinggi untuk menyederhanakan produksi dan mencapai skala ekonomi.

Kesimpulannya, sifat unik PTFE, ditambah dengan proses manufaktur yang rumit, terbatasnya ketersediaan bahan baku, dan persyaratan penyesuaian, berkontribusi pada jumlah pesanan minimum yang lebih tinggi untuk kabel dan kabel PTFE.

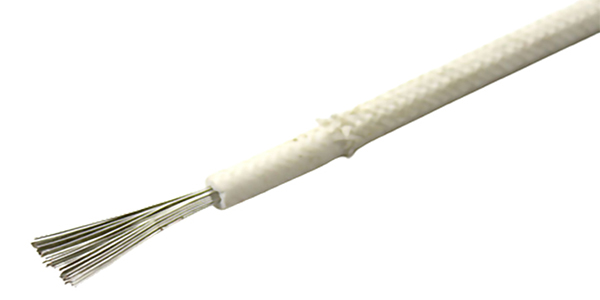

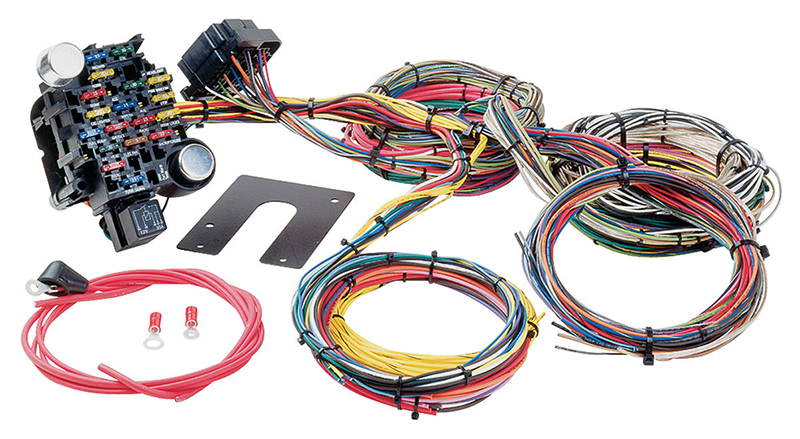

The production processes of silicone braided wire harnesses typically involve several steps. Here is an overview of the common production process:

1. Conductor : The process starts with selecting the appropriate gauge and type of wire according to the specific requirements of the wire harness. This includes considering factors such as voltage rating, current capacity, and environmental conditions.

2. Insulation : A layer of silicone insulation is applied over the braided wires. This insulation provides electrical insulation, protection from environmental factors like moisture, heat, and chemicals, and adds extra mechanical robustness.

3. Braiding: Silicone-coated fibers or threads are woven or braided tightly over the wires to protect and reinforce them. This braiding process helps to enhance the mechanical strength, flexibility, and abrasion resistance of the harness.

4. Wire Cutting and Stripping: The selected wires are cut to the desired length and then the insulation is stripped from the ends to expose the conductor.

5. Terminal and Connector Installation: The wire ends are then fitted with appropriate terminals or connectors, which can include crimp connectors, solder terminals, or specialized connectors based on the application requirements.

6. Wire Identification: If necessary, the wires in the harness are identified by adding labels, markers, or color-coded sleeves. This helps in the installation and maintenance of the wire harness.

7. Testing and Quality Assurance: Once the wire harness is assembled, it undergoes various electrical tests such as continuity checks, insulation resistance tests, and insulation integrity tests to ensure that it meets the required quality standards.

8. Final Assembly: Finally, any additional components such as protective sleeves, heat shrink tubing, or mounting brackets are installed to complete the wire harness assembly.

It’s important to note that the specific production processes may vary depending on Shoayer Cable.

Silicone-coated braided wire has various common applications, including:

1. Electrical insulation: It is used in the manufacturing of electrical cables and wiring harnesses, providing excellent insulation properties to prevent electrical leakage and short circuits.

2. High-temperature resistance: Silicone-coated braided wire is suitable for applications in high-temperature environments, such as in ovens, industrial furnaces, and automotive engines, where it can withstand extreme temperatures without melting or degrading.

3. Industrial heating elements: It is utilized in the production of industrial heating elements, such as those used in infrared heaters, electric furnaces, and heating pads, due to its ability to withstand high temperatures and provide electrical insulation.

4. Medical devices: The silicone-coated braided wire is used in the manufacturing of medical devices, including surgical tools, catheters, and diagnostic equipment, due to its biocompatibility, flexibility, and ability to withstand sterilization processes.

5. Automotive applications: It is widely employed in the automotive industry for engine-related wiring, sensor connections, and transmission systems, where it provides durability, resistance to heat and vibration, and protection against abrasion.

6. Aerospace and aviation: Silicone-coated braided wire finds application in the aerospace and aviation industries, where it is used for aircraft wiring, communication systems, and engine components, thanks to its excellent electrical properties and high-temperature resistance.

7. Electronic appliances: It is commonly found in various electronic appliances, such as computers, printers, televisions, and mobile phones, where it is used for internal wiring, connectors, and power supply cables due to its flexibility, tahan panas, and insulation properties.

8. Industrial machinery: It is utilized in the manufacturing of industrial machinery and equipment, such as robots, motors, and control systems, providing reliable electrical connections, protection against heat and chemicals, and resistance to mechanical stress and abrasion.

These are just a few examples of the common applications of silicone-coated braided wire. Its versatility, durability, and electrical properties make it suitable for use in a wide range of industries and applications.

FEP, or fluorinated ethylene propylene, is a type of fluoropolymer that is widely used in various industries. It offers several advantages and a few disadvantages as well. Here are some key points:

Advantages of FEP material:

1. Chemical resistance: FEP is highly resistant to a wide range of chemicals, including acids, bases, solvents, and corrosive substances. This makes it suitable for applications involving harsh chemical environments.

2. Non-stick properties: FEP has excellent non-stick properties, similar to PTFE (polytetrafluoroethylene), also known as Teflon. This makes it ideal for coatings and linings in applications where sticking or buildup of substances is undesirable.

3. Thermal stability: FEP can withstand high temperatures up to around 200°C (392°F) without significant degradation. This makes it suitable for use in applications involving high-temperature environments.

4. Electrical insulator: FEP has good dielectric properties, making it an excellent electrical insulator. It can be used in applications where electrical insulation is required, such as wiring and cables.

5. UV resistance: FEP is highly resistant to UV radiation, making it suitable for outdoor applications where prolonged exposure to sunlight is expected.

Disadvantages of FEP material:

1. Limited mechanical strength: Compared to some other engineering plastics, FEP has relatively low tensile strength and impact resistance. It may not be suitable for applications where high mechanical strength is required.

2. Difficult to process: FEP has a high melting point and is challenging to process compared to other thermoplastics. It requires special equipment and expertise for extrusion, molding, or other fabrication methods.

3. Cost: FEP is relatively expensive compared to other polymers on the market. This may limit its use in cost-sensitive applications.

It’s important to consider the specific requirements of your application and whether the advantages of FEP align with your needs.

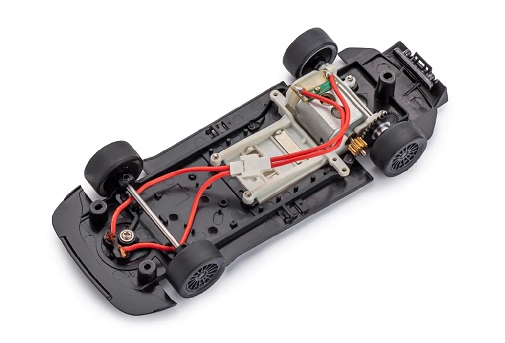

There are several commonly used electrical wires and cables in a car.

Here are a few examples:

1. Battery cables: These cables connect the car’s battery to the starter motor, alternator, and other electrical components.

2. Ignition wires: Also known as spark plug wires, these cables deliver high voltage from the ignition coil to the spark plugs, igniting the fuel-air mixture in the engine.

3. Wiring harness: This is a bundle of electrical wires that run throughout the vehicle, connecting various electrical components such as lights, sensors, switches, and controls.

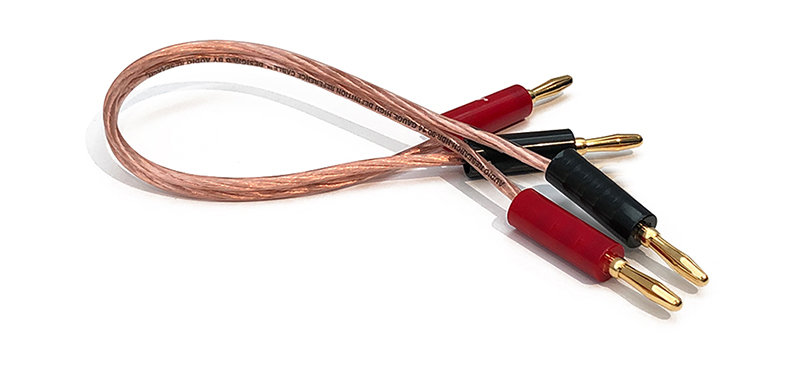

4. Speaker wires: These wires are used to connect the audio system’s amplifier to the speakers in the car.

5. Power cables: These cables carry power from the battery or alternator to various electrical components like the starter, lampu depan, sistem pendingin udara, dan perangkat berdaya tinggi lainnya.

6. Sensor cables: These cables connect various sensors in the car, seperti sensor oksigen, sensor temperatur, dan sensor kecepatan, to the engine control unit (ECU).

Harap dicatat bahwa ini bukan daftar lengkap, tetapi mencakup bagian dari kabel dan kabel listrik yang biasa digunakan di mobil.

Ada beberapa metode pelindung umum untuk kabel.

These include:

1. Braided Shield: A woven mesh of fine metal wires, seperti tembaga atau aluminium, memberikan fleksibilitas yang baik dan efektivitas perisai yang tinggi.

2. Foil Shield: A thin layer of metallic foil, seperti aluminium, diterapkan di sekitar konduktor atau isolasi untuk tujuan perisai.

3. Combination Shield: This method combines both braided and foil shields to provide enhanced shielding effectiveness.

4. Spiral Shield: A helically-wrapped metal strip or tape is applied around the conductor or insulation, providing moderate shielding effectiveness.

5. Serve Shield: Several insulated strands of wire are wrapped around the conductor in a helical pattern, enhancing the cable’s shielding effectiveness.

6. Metal Armor: A metal armor layer, usually made of steel or aluminum, is used to shield the cable from electromagnetic interference (EMI).

7. Metal Coaxial Shield: Used in coaxial cables, perisai ini terdiri dari tabung logam atau foil yang mengelilingi konduktor bagian dalam, memberikan perlindungan yang sangat baik terhadap EMI.

8. Foamed Shield: A foam material, seperti polietilena atau polipropilena, digunakan untuk mengelilingi konduktor atau isolasi dengan sifat pelindung.

Metode pelindung ini umumnya digunakan dalam berbagai aplikasi untuk melindungi kabel dari interferensi elektromagnetik eksternal dan memastikan integritas sinyal.

ETFE (Ethylene Tetrafluoroethylene) insulation for electrical wire and cables offers several advantages:

1. Excellent thermal stability: ETFE insulation can withstand high temperatures without degrading, making it suitable for applications where heat resistance is crucial.

2. High mechanical strength: ETFE insulation has excellent tensile strength and durability, making it resistant to cuts, abrasion, and impact. It can withstand harsh environmental conditions and is less prone to damage compared to other insulating materials.

3. Chemical resistance: ETFE insulation is highly resistant to chemicals, oils, solvents, and various corrosive substances. This property makes it suitable for applications exposed to potentially damaging environments.

4. Electrical properties: ETFE has low dielectric constant and low dissipation factor, resulting in efficient electrical insulation. It offers good dielectric strength and is capable of withstanding high voltages.

5. Lightweight: ETFE insulation is significantly lighter than many other insulation materials, making it suitable for weight-sensitive applications that require flexibility and ease of installation.

6. Weather resistance: ETFE is resistant to UV radiation, moisture, and weathering effects. It does not deteriorate or become brittle over time, ensuring long-term performance even in outdoor or harsh environments.

7. Low friction coefficient: ETFE insulation has a low surface friction coefficient, allowing for easy cable handling and installation.

These advantages make ETFE insulation a popular choice in various industries, including aerospace, automotive, electronics, and renewable energy.